About

DENSBAK F Range

What is DENSBAK F?

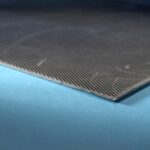

Our industrial grade DENSBAK F range is used for a variety of soundproofing applications. DENSBAK F uses lower density calcium-based fillers with the same low VOC and fogging content and low odour characteristics as our Automotive Grade [DENSBAK F40]. The material can be faced on one or two sides with a variety of substrates to increase mechanical strength and promote adhesion to various substrates.

Applications

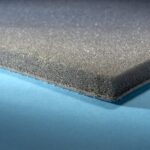

DENSBAK F can be used in flooring applications and combined with a wide range of cellular foam products and is widely used for acoustic floor mats.

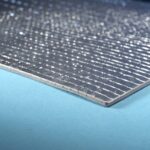

All our DENSBAK F products can be supplied faced with non-woven or jute/hessian facings to increase mechanical strength and aid adhesion.

Reinforced DENSBAK F products are typically used in plywood floor constructions, air ducts, and partition walls.

DENSBAK FB

DENSBAK FB is a high-density version of our DENSBAK F product, which means the product is thinner at the same mass (kg/m2) than its DENSBAK F equivalent.

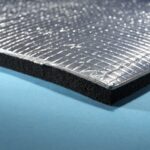

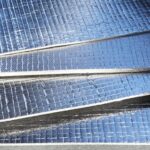

DENSBAK FB AL is manufactured with a factory-applied embossed or smooth aluminum foil finish and is typically combined with acoustic foams or glass quilts when used for duct and pipe wrapping applications.

Available facings:

- Bilaminate films

- Hot melt adhesives

- Self-adhesive tapes

- Class ‘O’ Aluminium

- Non-Woven Scrims

- Jute/Hessians

- Needle felts

Key Characteristics

DENSBAK F has a recommended static Service Temperature of -10°C and the material will start to soften at 60°C. The material is tested to ISO 3795 and FMVSS 302. It is however not designed to be fireproof and prolonged exposure at high enough temperatures could cause the material to self-ignite.

Materials can be produced according to individual customer requirements subject to minimum manufacturing quantities.

- in sheets and roll form

- in a range of weights from 1.25kg/m2 (1/4 lb/ft) up to 15kg/m2 (3 lb/ ft)

- in widths up to 2000mm (78 inches)

Please refer to the Technical Data Sheet (TDS) for more information.

Key features & benefits

DENSBAK F products are free from substances of very high concern (SVHC) like lead, halogens and unrefined aromatic oils.

DENSBAK F is thin and flexible which allows easy installation round corners, pipework, square ducting and steel framework without cracking and tearing. Good lay flat (high memory form) even at cold temperatures (for example, after warehouse storage).

High speed mixing process coupled with super cooling means DENSBAK F products are physically stable and robust. DENSBAK® F can be warehoused in cold storage without risk of cracking and product deterioration. Under normal environmental conditions of use the material does not chemically degrade or change its physical properties over time.

DENSBAK F has specifically been designed to provide better slip resistance and help safer installation on floors. It is manufactured with either one side embossed and one side smooth or two sides embossed. The embossed surface increases the surface area to aid adhesion to other laminates.

Niko extrusion process means DENSBAK F has no oily or greasy residues (like bitumen based or viscous/sticky products) on the surfaces and therefore does not stain and prevents the product from sticking together during storage and installation in warmer temperatures. It also means DENSBAK F does not require interleaves so reduces waste disposal costs.

Industries served

Automotive

DENSBAK F can be combined with various substrates used to make retrofit soundproofing kits used in boots and cabin floors which can help to reduce road, exhaust and tyre noise.

Building and Construction

Acoustic mass layers can improve sound insulation for building envelopes and are found in built-up roofing systems, external wall cladding systems as well as internal walls and floor systems. DENSBAK products are used to great effect in the HVAC industry for sound Acoustic roofing membranes for built up systems.